- Contact:Minister Xu

- Mobile:13841408476

- Tel:024-44837288

- Fax:024-44837004

- E-mail:xuming58@126.com

- Web:m.natashaterry.com

- Address:No.110 XiangHuai Road

Benxi Economic Development Zone

Liaoning Province

NSK Develops High Efficiency Motor Bearings

26 Oct,2018 NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) has developed new high-efficiency bearings for high-efficiency motor applications. The new bearings reduce energy loss to an unprecedented low level.

Development Background

Product Features

Product Benefits

Industrial motors account for an estimated 40% of the world's electricity consumption. Accordingly, the new bearings are set to make a significant contribution to reducing industrial-and global-electricity consumption. NSK is targeting 4.5 billion yen in yearly sales of the bearings by 2025.

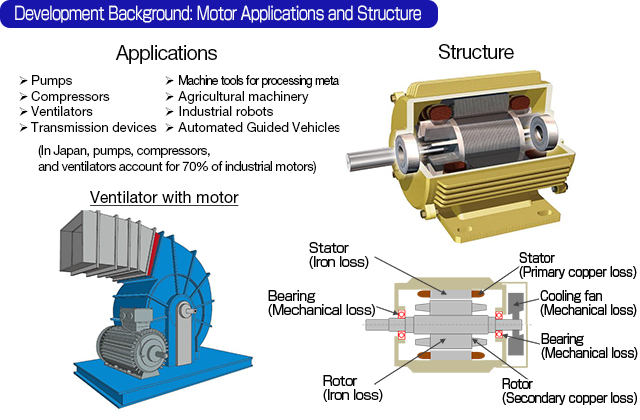

Consumers and businesses alike are increasingly concerned about preserving the global environment, and CO2 emissions from industrial sources are facing intensifying scrutiny and criticism. In industrial applications, motors are widely used to operate pumps, ventilators, compressors, and other such components and equipment. On the whole, such applications are estimated to account for 40% or more of global electricity consumption. Many countries are now further regulating energy consumption, including mandatory requirements for motor efficiency.

Although mechanical loss from bearings typically only accounts for 1% of the energy input to the motor, loss at each step from motor to movement has a cascading effect that results in significant loss overall. This has created demand for even further reduction of energy loss in bearings.

Development was also rooted in the NSK Mission Statement, which expresses our dedication to responding to the needs of society and protecting the global environment.

Reduced Energy LossThe new bearings use a special grease developed by NSK. By optimizing the amount of grease applied, we reduced stirring resistance, and achieved a 60% reduction in energy loss for bearings with pressed steel cages. Up to 80% reduction in energy loss is achieved with a plastic cage.Longer LifeThe special grease developed by NSK significantly reduces internal wear in the bearing. Compared to previous products, the new bearings have upward of 2.7 times longer service life.

The new high efficiency bearings contribute to reducing energy consumption of industrial motors, thereby helping protect and preserve the global environment. NSK will continue to develop products to meet the evolving needs of society.